Liquefaction of biomethane

More information

The new plant for the production of liquid biomethane (also known as BioLNG), developed in collaboration with Ham Italia, makes the advanced biomethane of Caviro Extra liquid through a cryogenic liquefaction process performed at -150°C.

The biomethane obtained from agri-food chain waste through the anaerobic biodigestion process and the subsequent biogas upgrading phase is then transformed into BioLNG and represents a tangible solution for the decarbonisation of heavy transport.

The plant has a production capacity of almost 9,000 tonnes of liquefied biomethane a year, enough fuel for heavy goods vehicles to travel 20 million kilometres.

Potential

| Parameter | Average value |

|---|---|

| Biomethane gas in | 1.600 Nm³/h |

| Liquid biomethane out | 27 tonnes/day |

| Max. production | 8,900 tonnes/year, equivalent to 12,000,000 m3/year |

| LNG storage capacity | 49,2 tonnes |

Technology

- Purification with CO2 removal (selective absorption in solvent) up to 50 ppm residual

- Thrust dehydration (TEG absorption) up to 1 ppm H2O residual

- Double compression closed cryogenic cycle – inert nitrogen gas expansion (reverse Brayton cycle)

- Biomethane Liquefaction in Cold Box

- Cryogenic tank storage: -150°C at 2 barg

- Measurement and analysis at liquefier inlet and before loading into a tank

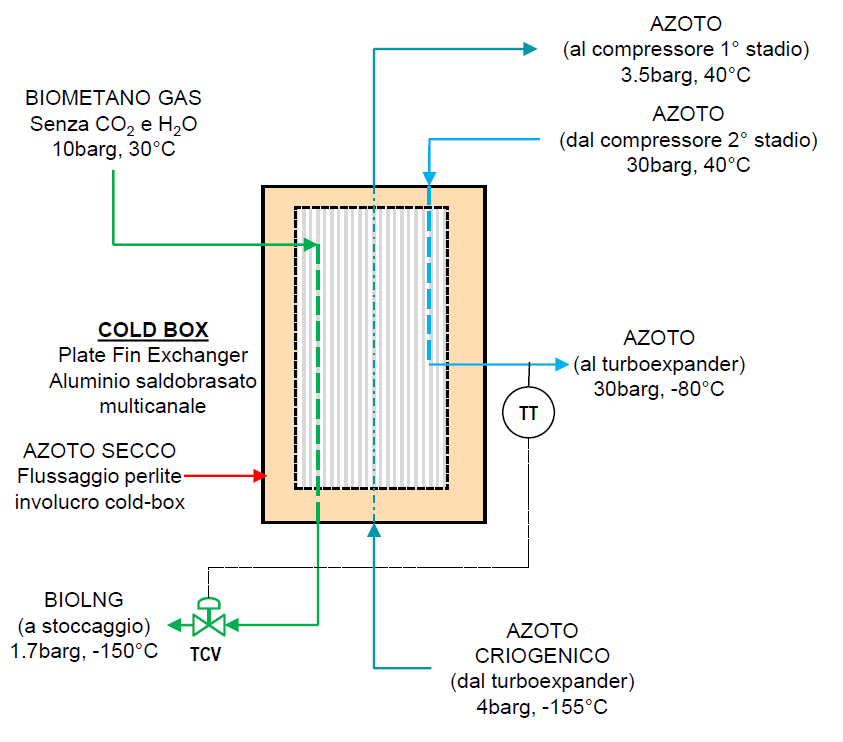

Liquefaction – Cold Box

- Biomethane liquefaction takes place by countercurrent cooling in a multi-channel plate “cold box” heat exchanger

- The fluid used for cooling is inert nitrogen in a closed cycle that reaches cryogenic temperatures (-155°C) by compression at 30 barg and subsequent expansion in a 4 barg turbine

- The nitrogen is self-produced through filtration of the ambient air in a membrane module, in order to reach a purity of 99.99%

- In addition to the refrigeration cycle, nitrogen is also used to maintain the flow of the insulation chamber with perlite around the cold box and LNG storage tank

Plant construction

Contact us

Would you like to try our Extra Eco-Energy?

Write to us for more information, our experts will get back to you as soon as possible

Alessandro Nespeca,

Eco-Energy Contact Person